The wiring for your network, or Physical Layer as it is called around the IT water cooler, is probably the least expensive portion of you network. It is, however, probably the most important. When a device goes down, the first thing that is checked is connectivity. Does the device see the network? This is the function of your cable plant. The cable plant, or network infrastructure, (I know, a lot of terms for the same thing) consists of the following components: a patch cable from the network switch port to the patch panel port, a horizontal data rated cable from the patch panel to a work station outlet, and then another patch cable from the outlet to the device. If a ticket comes in about a down device, the first place you go to is your network closet.

If it looks like this,

you have a long day ahead of you.

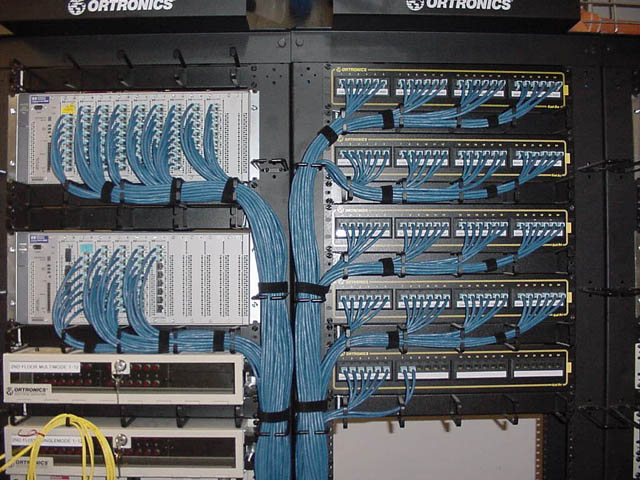

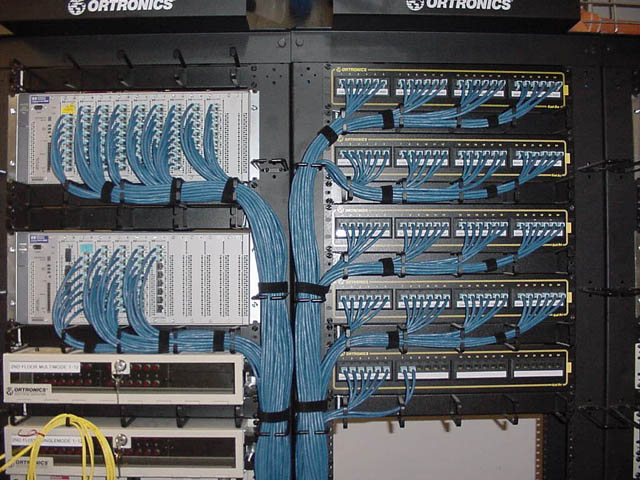

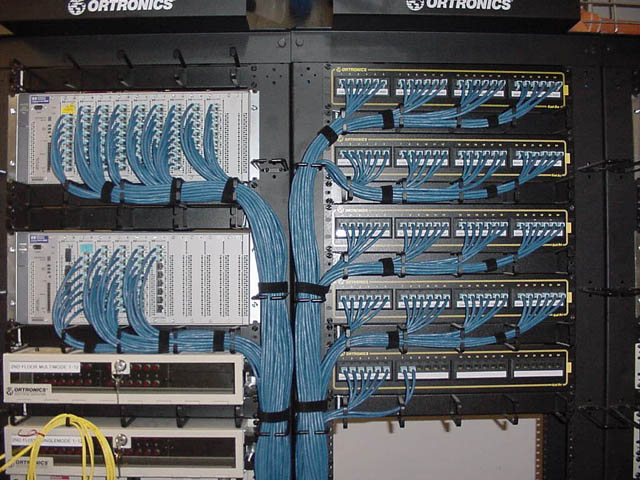

If it looks like this,

you have a better chance of having dinner with the family.

Cable management is very easy if you remove the human factor. The worst enemy of cable management is an undisciplined tech. You can spend all kinds of time and money setting up your racks and panels with management devices and labeling, but once you have patching being done without following the procedures that are in place, you can look forward to long days.

What are those procedures?

First, invest in cable management hardware. Both horizontal and vertical managers come in a variety of flavors from every hardware, rack and cabinet manufacturer. They will use additional rack spaces and the verticals will increase the foot print. You can cheat a little bit and get the management with covers. But remember, if you have it, use it!!

Second, make sure your labeling is easy to follow…and easy to add to. It sounds stupid, but make sure it is the same at both ends. You want to have a sequential system that won’t go down the tubes as soon as you add a cable. Get as-built plans from your contractor at the end of the project and keep them in the closet. They always get referenced. We’ll cover the EIA/TIA 606 labeling standards in a future blog.

Third, have different lengths of patch cords on hand. A rack full of 10’ patch cords does not make for a neat rack. Several manufacturers now offer small diameter Cat 5e and Cat 6 patch cords in varying lengths. They may not be available in every color yet, but all the common colors are available. These cords take up less space in the management panels so you’re not closing the covers on the management like an overfilled suitcase.

Fourth, document, document, document. Have a spread sheet that everyone has access to so that when changes are made in the closet, changes can be made on the spread sheet. As mentioned before, have as-built drawings in the closet and electronically on the network. Update the drawings with every change. If an area gets renovated or reconfigured, get the new drawings. Proper documentation could save you visits to the closet when troubleshooting.

These are some of the more common procedures that you can adapt to your own environment. The better the procedures that are in place, the easier your life will be. A closet doesn’t have to be a showplace, but don’t have it be someplace that your CIO avoids when showing his colleagues his network.

Until next time…